|

|

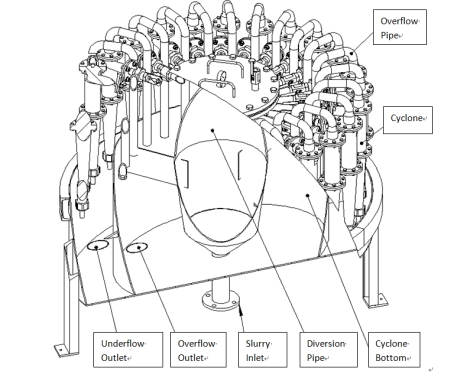

Hydrocyclone Group

1.Product description The Hydrocyclone Group is a grading device that uses centrifugal force to accelerate the sedimentation of ore particles. It requires pressure to feed the mine, so it consumes a large amount of power, but has a small footprint, low price, large processing capacity, high classification efficiency, and can be obtained very fine. The overflow product is mostly used in the classification equipment of the second section of closed-circuit grinding.

2.Operating Principle

The strong centrifugal force is used to achieve the separation of the mixture under high speed rotation. For example, the classic static hydrocyclone uses external pressure to push the feed mixture into the cyclone at a relatively high speed. Since the mixture moves along the tangential direction of the cyclone, this will cause the liquid to move along the cylinder. The wall makes a rotational movement, which is generally called an external swirl. The particles in the outer swirl are subjected to centrifugal force. If its density is greater than the density of the surrounding liquid, the centrifugal force it receives will become larger and larger. Once the centrifugal force is greater than the liquid resistance caused by the movement, the particles will overcome this resistance The wall moves in the direction of the wall and is separated from the surrounding liquid. The particles that reach the wall are pushed by the liquid above the cyclone and move down the wall. When it reaches the underflow port, it will collect into a suspension with a high degree of consistency and be discharged from the underflow port. The separated liquid rotates downward and continues to move. After entering the cone section, the liquid rotation speed is accelerated because the inner diameter of the hydrocyclone is gradually reduced. Due to the uneven pressure distribution in the radial direction of the liquid when the vortex is generated, the closer the axis is, the smaller it is, and the axis approaches zero. Becoming a low pressure zone or even a vacuum zone causes the liquid to move in the direction of the axis. At the same time, because the bottom flow port of the hydrocyclone is greatly reduced, the liquid cannot be quickly discharged from the bottom flow port, and the overflow port in the center of the top of the swirl chamber is moved to a part of the liquid due to being in a low pressure region, thereby forming an upward rotating motion And discharged from the overflow port.

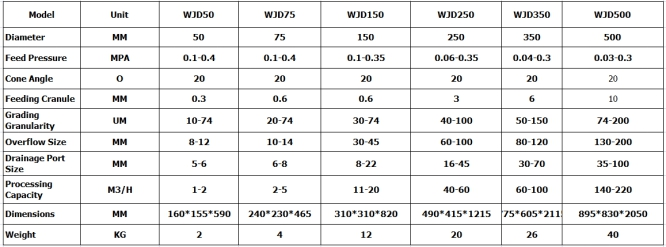

3.The Main Technical Parameters

4. Application Scope The Hydrocyclone is a device fro separating and removing heavy and heavy particles such as sediment from sewage. Sometimes used for mud dewatering. It is divided into two types: pressure type and gravity type. It is usually made of circular colum structure or metal tube. The water enters the tangential line by the structure or the upper part of the metal tube by pressure or gravity. Under the action of centrifugal force, the coarse and heavy particulate matter is thrown to the wall and rotated downward to discharge together with the formed concentrated liquid. The esmaller particulate matter is rotated to a certain extent and then discharged with the secondary upper vortex. 5.Shpping

|