1.Product description

The product has the following characteristic:

The magnetic field strength is high. The magnetic system is made of high-performance rare earth neodymium iron boron material. The polypole surface is wide, the number of magnetic poles is large, the magnetic induction intensity is high, the magnetic field gradient is large, and the local high magnetic field can reach 13000GS.

The magnetic plate area is large, the current wide direction can reach 2.8 meters, a large length direction up to 3 meters.

Uniform fabric: double-layer perforated fabric, smooth and uniform, thin material layer.

Unloading iron clean: Customized and developed a variety of special unloading iron belts for users to choose, using high-strength and high-quality composite materials, long service life and obvious effect of unloading iron.

Energy saving, water saving: only one small power drive motor, low consumption electrode, unique controllable water supply system design, saving water resources.

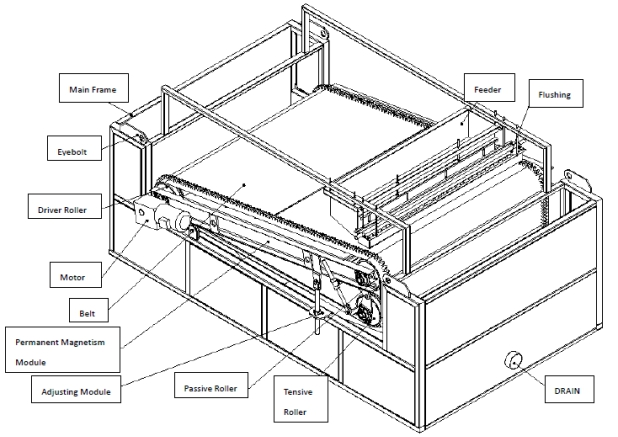

2.Operating Principle

The raw ore slurry enters the falling hopper first, and is sorted by the falling hopper buffering and adjusting the belt spreading on the magnetic plate. The falling hopper is provided with a mesh or a groove and a blocking plate provided at the discharge port, thereby ensuring uniform falling and controlling the amount of slurry falling. A water leveling device is arranged beside the falling hopper, including a spray pipe which is located above the magnetic separation slope and is connected to the flushing water inlet pipe, and a sprinkler with a uniform water hole at the bottom directly below the spray pipe is used to clean the belt. The material can be magnetically mixed under the action of the belt. At the same time, under the washing effect of the water flow, the slurry with magnetic materials is demagnetized by the belt conveyor belt plate machine. There is magnetic slurry separation. After finishing the beneficiation process, the whole machine has low power, large processing capacity and high magnetic field strength, which can better report the original ore materials for purification, thereby obtaining greater benefits.

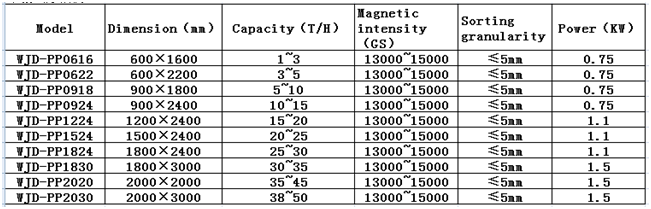

3. The Main Technical Parameters

4. Application Scope

Wet processing non-metal removal of iron, especially fro wet removal of non-metallic minerals , such as quartz sand, potassium sodium feldspar. In addition, it has good sorting effect on weak magnetic minerals, such as hematite, limonite, mirror iron ore, garnet, siderite, manganese ore and antimony ore.

5.Shipping