1.Product description

The small Electromagnetic Slurry Magnetic Separator has high magnetic field, uniform magnetic field distribution, high gradient , remarkable effect of removing iron, small floor space, and can provide tractionable mobile slurry iron removal workstation according to customer requirements; This series of products adopts water and oil double cooling. The design scheme is convenient for heat dissipation or heat dissipation. When the equipment is continously operated, the temprature of the coil can be controlled within the range below the temperature control line to extend the service life of the coil, and at the same time stabilize the excitation output the coil; the magnetic medium is special. Made of the stainless steel, it has good corrosin resistance and magnetic properties. When the excitation coil is energized, the magnetic medium has a good magnetic field converging effect, and the gradient magnetic coil is degaussed quickly after failure; The semi-automatic or fully automatic system can be formulated according to the customer’s production requirements.

2.Operating Principle

When the slurry flows into the magnetic zone, the strong magnetic minerals are adsorbed on the surface of the cylinder, the weak magnetic and non-magnetic minerals are separated and removed, and the strong magnetic minerals adsorbed on the surface of the cylinder are carried out of the magnetic zone with the rotation of the cylinder. The rotary type is suitable for the separation of fine (medium strong) magnetic minerals. Due to the effect of high-speed rotation, the magnetic rollover times of magnetic particles are much higher than that of ordinary magnetic separators. This has a remarkable effect on breaking the magnetic agglomeration and increasing the ore-rich ratio after separation, the minerals are separated into magnetic and non-magnetic materials, which are discharged from their discharge ports respectively. The machine is suitable for roughing and cleaning of 0.6-6mm ores.

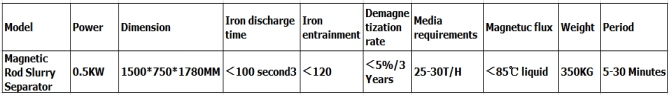

3.The Main Technical Parameters

4.Application Scope

In the ceramics, slurry, shafting, mining, chemical, electronics, food and other industries need to remove iron.

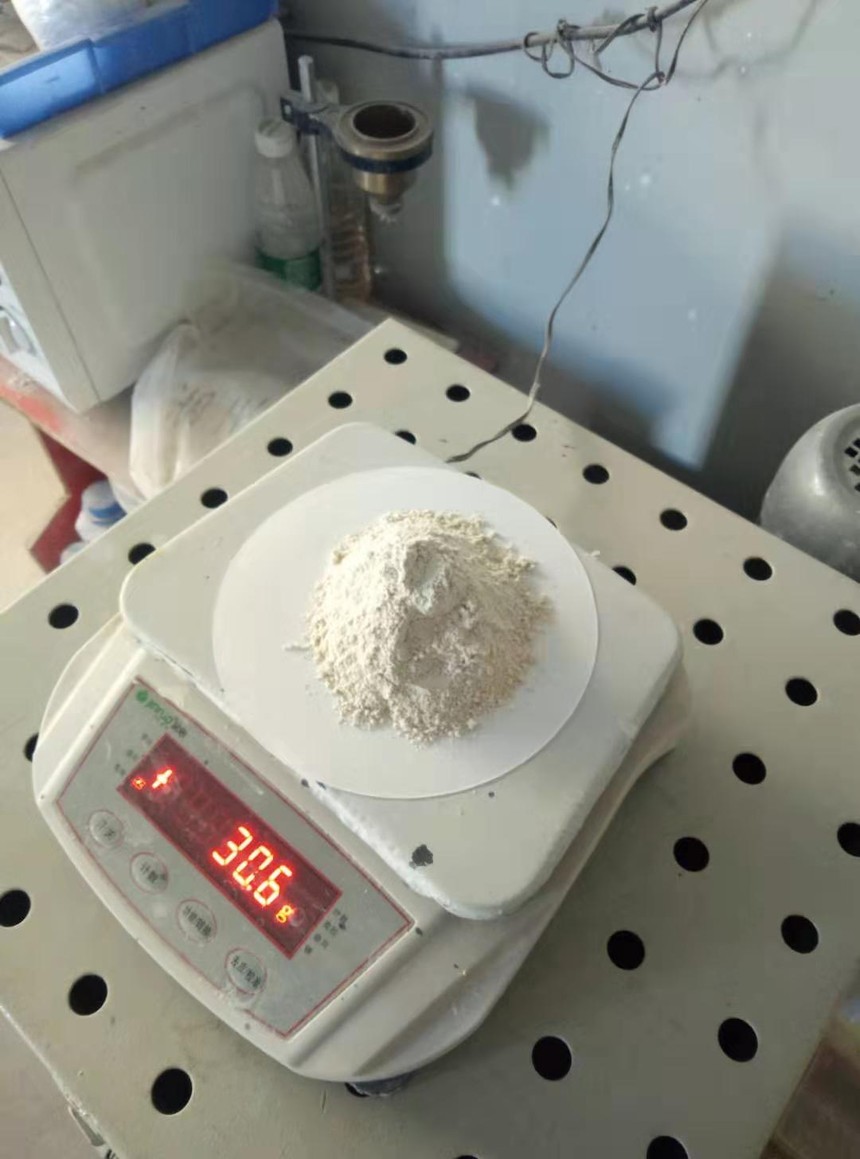

5. Our laboratory