1.Product description

Automatic Oil-cooling Electromagnetic Slurry Separator has the following characteristics:

Output voltage can be adjusted, according to the nature of the specific ore, Automatic Oil-cooling Electromagnetic Slurry Separator output voltage and save power consumption.

The cooling method of water and oil double cooling can reduce the internal temperature rise and minimize the attenuation speed of magnetic field strength, thus prolonging the service life of the magnetic separator.

Automatic Oil-cooling Electromagnetic Slurry Separator saves about 30% energy than Automatic Oil-cooling Electromagnetic Slurry Separator.

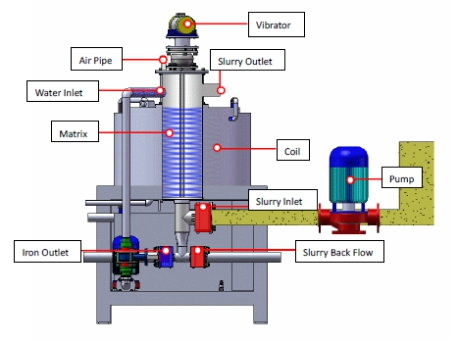

2.Operating Principle

When the slurry flows into the magnetic zone, the strong magnetic minerals are adsorbed on the surface of the cylinder, the weak magnetic and non-magnetic minerals are separated and removed, and the strong magnetic minerals adsorbed on the surface of the cylinder are carried out of the magnetic zone with the rotation of the cylinder. The rotary type is suitable for the separation of fine (medium strong) magnetic minerals. Due to the effect of high-speed rotation, the magnetic rollover times of magnetic particles are much higher than that of ordinary magnetic separators. This has a remarkable effect on breaking the magnetic agglomeration and increasing the ore-rich ratio after separation, the minerals are separatedinto magnetic and non-magnetic materials, which are discharged from their discharge ports respectively. The machine is suitable for roughing and cleaning of 0.6-6mm ores.

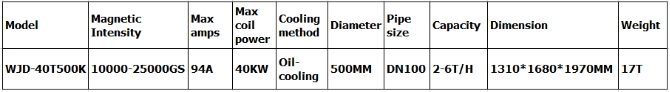

3.The Main Technical Parameters

4.Application Scope

Automatic Oil-cooling Electromagnetic Slurry Separator is suitable for non-metallic minerals, such as quartz, feldspar, high territory and other minerals. Wet iron removal and purification, can also be used as rare earth metal recovery, steel plant, power plant wastewater treatment, electromagnetic positive and negative Extreme material wet method iron removal and other purposes.

5.Shipping